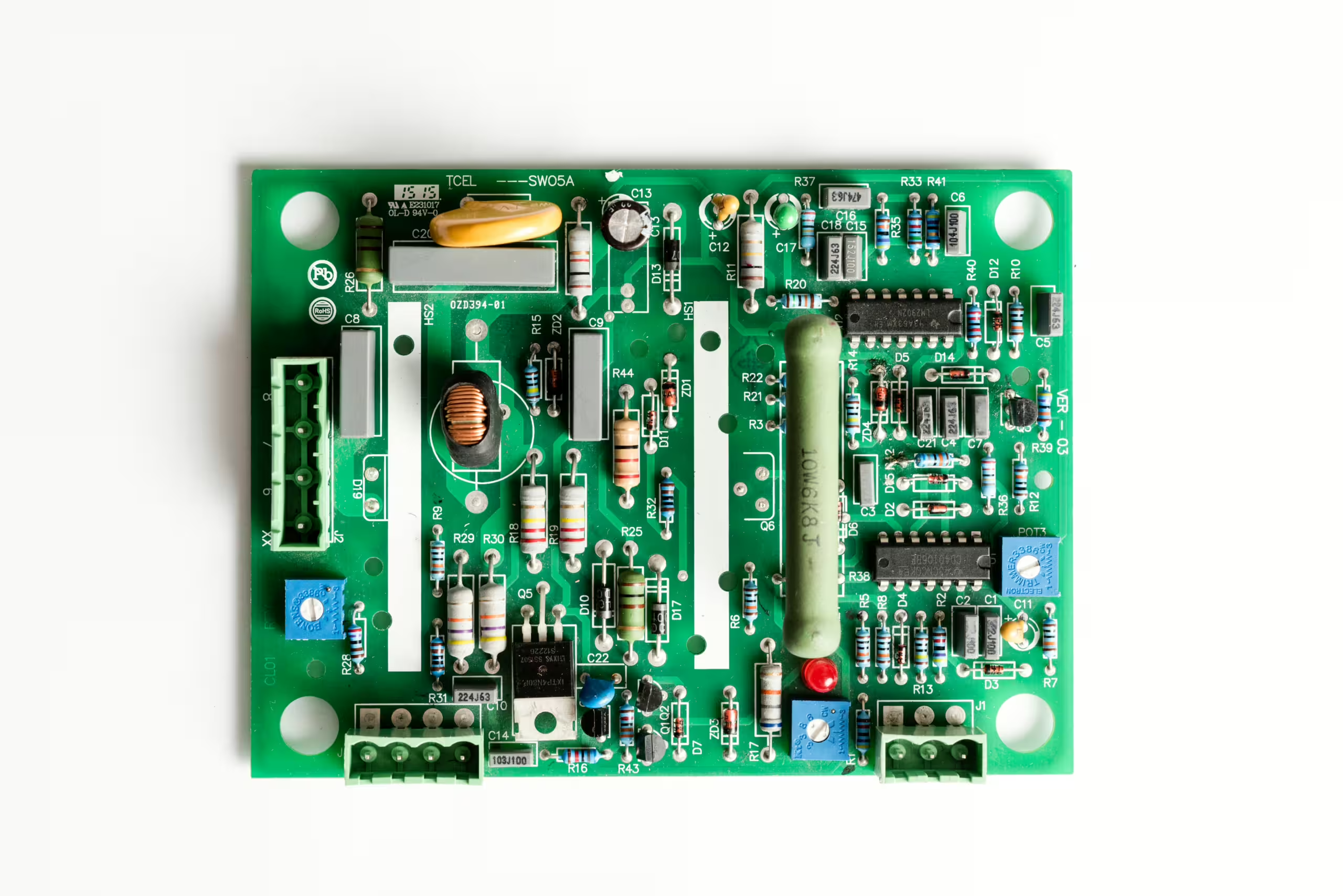

Why do high-quality, multi-layer PCBs commonly use via-in-pad and immersion gold processes? Let’s discuss each process:

Via-in-Pad Due to the complex structure of high multi-layer boards and the intricacies of routing, especially around BGA (Ball Grid Array) locations, the via-in-pad technique is employed. This involves drilling vias directly into the pads, filling them with resin, and then plating them with copper. This method eliminates the need for separate traces to route through vias, enhancing routing efficiency and saving space on the board. Moreover, since the vias are covered, the soldering is more robust and reliable, as there are no exposed holes.

Immersion Gold Process This involves a chemical deposition of a gold layer on the surface of the solder pads, which prevents oxidation of the pads and enhances solderability. The thicker the gold deposit, the smoother the surface, which is more conducive to processes like SMT (Surface Mount Technology). The immersion gold provides a flat, clean surface that improves the reliability and quality of the solder joints.